|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Control Methodology (TCM) |

| All of our training courses and programs are "hands-on", and are offered at the client's facility (on-site), anywhere in the world. |

| Course Description |

|---|

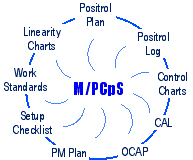

| The Total Control Methodology (TCM) is a statistical process control system that integrates the necessary statistical tools to establish a preventive and continuous plan to control input variables (machine parameters and process variables) and monitor output variables (product characteristics). TCM maintains processes stable, predictable, capable of producing within specification limits, and most importantly, it fool-proofs the process of defects. A typical SPC course teaches you how to control product quality by control charting product characteristics after the product is produced. This type of control is reactive. TCM is proactive! TCM teaches you how to control the process and process parameters -- independent variables, or the input to the process. As a consequence, this will permanently assure control of the output of the process (product characteristics), and will result in non-defective product quality. The integration of SPC (control charts) with other tools such as Positrol Plans and Positrol Logs, Corrective Action Logs and “Out-of-Control” Action Plans, Linearity Charts, Preventive Maintenance Plans and Work Standards, launched the Total Control Methodology. TCM was implemented at Motorola (starting in late 1980s), in production as the final stage and culmination of a Machine/Process Capability study. In this course, you will learn how to apply Shewhart control charts, Positrol Plans, Traceability Logs, and OCAPs, as well as all the other new elements of TCM. |

| The Process | Stages of the TCM Methodology | Factum |

|---|---|---|

|

|

TCM was first implemented at Motorola's Government Electronic Group (FMU-139) by Mr. Perez-Wilson, in production, as the final stage and culmination of an MPCpS® study. Total Control Methodology is the integration of a number of critical production control methods, such as: Positrol Plans, Positrol Logs, Corrective Action Logs, Corrective Action Plans, Linearity Charts, Preventive Maintenance Plans, Setup Checklists and Work Standards. |

| Benefits of the Total Control Methodology | What is TCM? |

|---|---|

|

The Total Control Methodology, TCM, is a system that integrates the necessary tools to establish a preventive and continuous plan to control critical machine parameters, significant process variables and product characteristics. This maintains a stable, capable and fool-proof process free of defects. |

| We are Proud of Our "Hands-On" Training Approach |

|---|

| We take participants through lectures in which they learn the tools, methods, and concepts. Then, we help them to apply the tools to their own processes. This is, by far, the most efficient way to learn the application of statistical process control methods and the Total Control Methodology. |

| Home | | ASC | | M/PCpS | | Six Sigma | | VRI | | Training | | Books | | Software | | Articles | | Clients | | Email Us |

| © Copyright, 1995-2024, Advanced Systems Consultants. All Rights Reserved. Scottsdale, Arizona 85261-5257 |